- Home /

- Industries /

- Aggregates

AGGREGATES INDUSTRY SOLUTIONS

Unicast provides the aggregates industry with customized wear parts that can endure wear caused by repetitive crushing and grinding, and screening and feeding of abrasive materials.

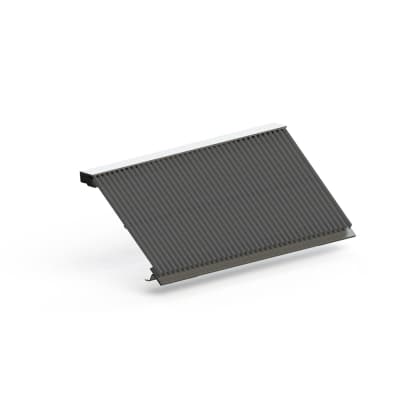

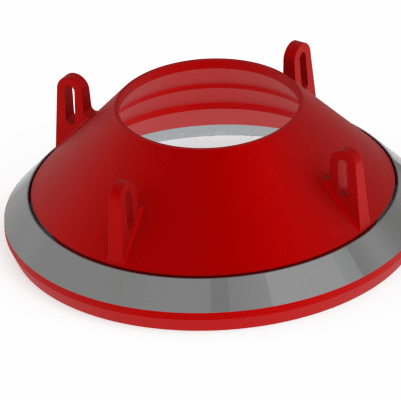

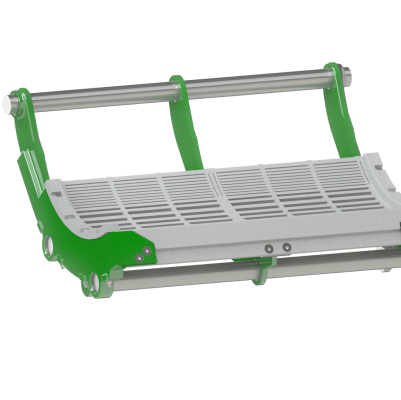

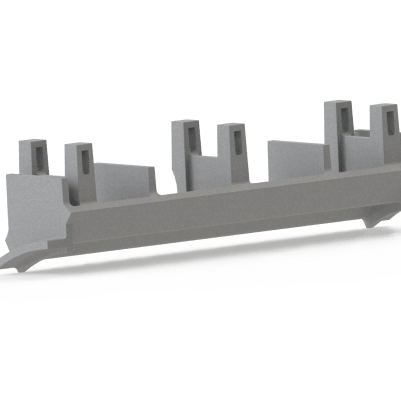

Our aggregates industry wear parts are built to outperform OEM wear parts and boost productivity and efficiency by keeping machines up and running. Alloys are chosen to suit the application and include manganese steels, titanium carbide, and CRA ceramic for incredible wear life. Unicast manufactures parts for gyratory, cone and jaw crushers, horizontal and vertical shaft impactors, hammermill parts, feeders and grizzlies.

We have a rotating supply of in-stock wear parts ready for quick delivery. Unicast is committed to keeping your plant or mine online and maximizing your efficiency through innovative wear part solutions.