- Home /

- Industries /

- Coal

Coal Industry Solutions

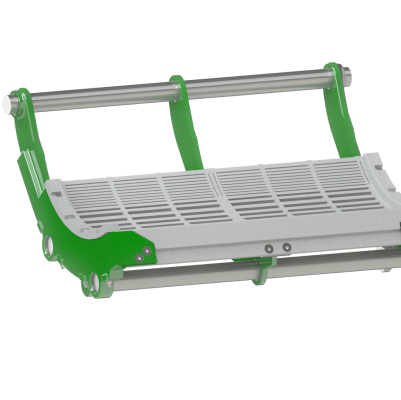

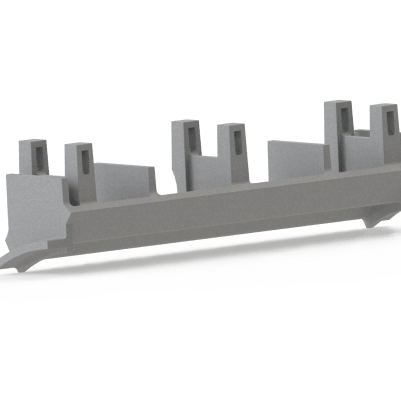

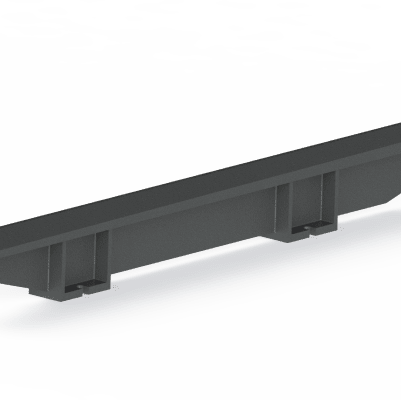

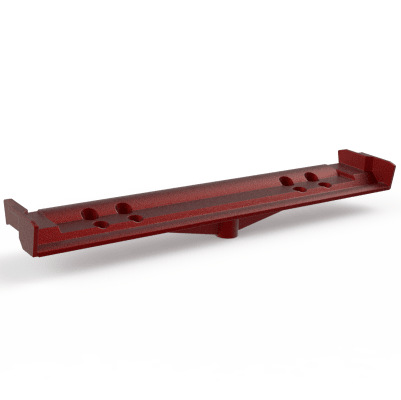

Unicast supplies cost-effective and custom-made solutions for wear issues in the coal industry. From cast breaker plates to wear-resistant chute and hopper liners, our engineers offer customized wear solutions for highly-abrasive environments.

With a holistic approach to wear part design that improves original equipment’s weight, weight distribution and alloy selection, our coal industry products include wear parts for hammermills, roller and ball mills, feeders and rotary breakers.

We have a rotating supply of in-stock wear parts ready for quick delivery. We also specialize in customized and cost-cutting solutions designed for particular wear challenges.