- Home /

- Industries /

- Mining

Mining Industry Solutions

From gold mines in Nicaragua to copper operations closer to Unicast headquarters in British Columbia, our wear parts and valves have boosted productivity on mines across Canada, the U.S. and Central America for over a decade.

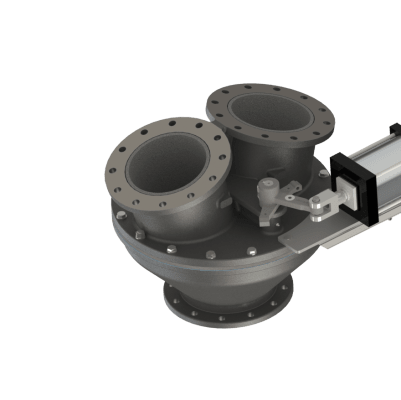

Unicast wear parts address the full range of mining industry applications, from crushing, screening, feeding, grinding, power transmission and slurry transport. Our mining industry products include parts for gyratory, jaw, roll and cone crushers, feeders, SAG & ball mills, mining valves, roll crushers, sizers, and grizzlies.

We have a rotating supply of in-stock wear parts ready for quick delivery. We also specialize in customized and cost-cutting solutions designed for particular wear challenges.

Popular mining wear part products include:

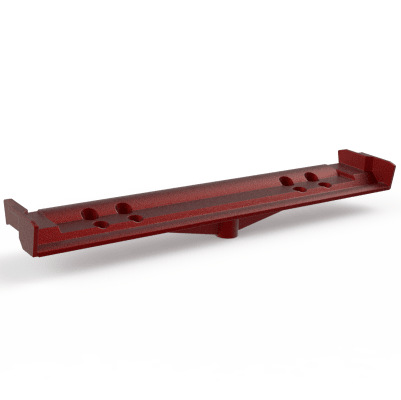

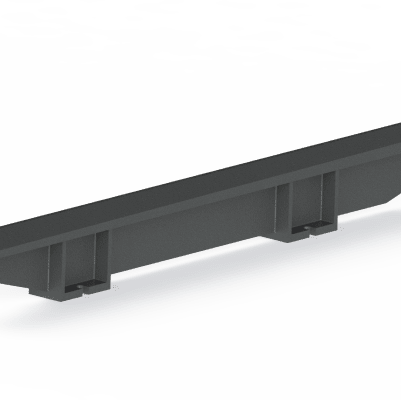

- Our austenitic manganese steel apron feeder pans are cast for exact fit and work harden under high-load conditions and impact. Our one-piece casting method eliminates failure due to weld cracks - a common problem with traditional fabrication - and ensures greater durability and wear life. Pans are also available with titanium carbide inserts.

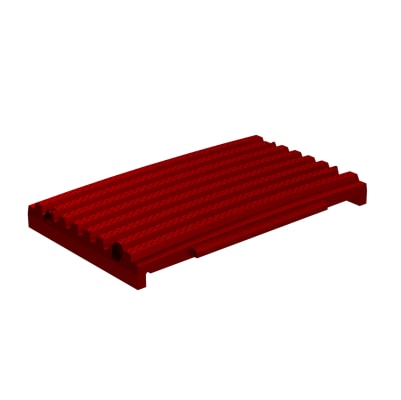

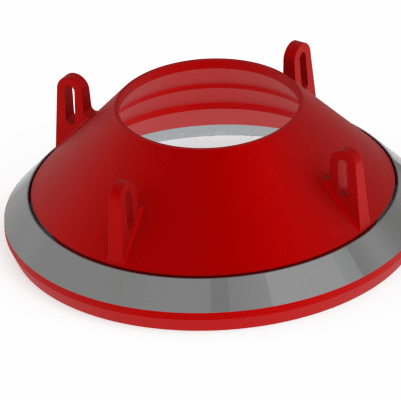

- Our jaw crusher wear parts include jaw plates, cheek plates, wedges cast in a work-hardening manganese alloy for optimum performance. One client saw a wear life increase from 3.5 days to 30 days with a Unicast titanium carbide jaw plate.

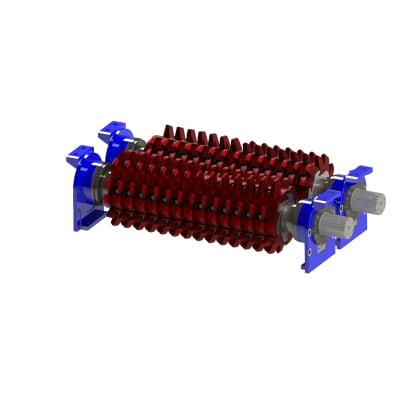

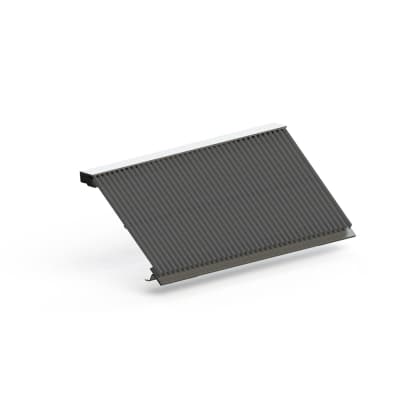

- From feed head to discharge end, our custom-made liners optimize ball and SAG mill performance. Unicast engineers will provide a perfect-fit design and alloy selection after on-site measurements to suit your application.