News & Articles

June 24, 2024

Unicast's Industry leading diverter valves will be featured in upcoming cement magazines

Check out the upcoming Cement Products and International Cement Review.

April 08, 2024

Unicast and other Decisive Dividend Subsidiaries raise over $14,000 for Hockey Helps the Homeless

the Decisive Dividend team and its subsidiaries, Blaze King, Slimline and Unicast were thrilled to participate in Hockey Helps the Homeless that brought out the best in camaraderie. A huge thank you to our staff who laced up the skates: Jeff Schellenberg, Tyler Senft, Daryll Lowry, Patrick Hennessey, Shawn Boudreau, Alex Mackinder, Keith Paton, Mark Watson, and our entire team for their unwavering dedication! Together, we contributed to raising over $14,000 for Hockey Help the Homeless, making a meaningful impact in our community.

March 22, 2024

Recent Supply Chain Trends – “Values Based” Sourcing in the Wear-Part Business.

Unicast has seen some interesting supply chain trends since the end of COVID. Many of our customers have requested wear-parts from countries that share their corporate or even national values. There is a definite trend in “values-based” sourcing sometimes referred to as near-shoring or friend-shoring.…

December 14, 2023

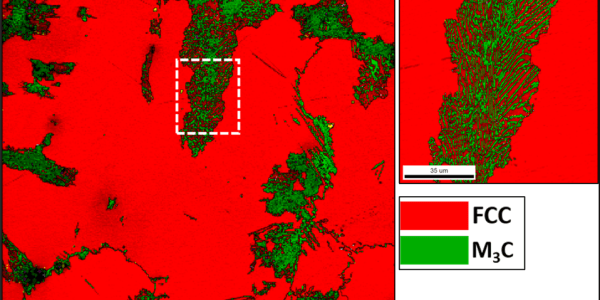

Microstructure Evolution and Austenitic Grain Refinement of Ti-Modified High Mn Steels During Solution Annealing Heat Treatment

Austenitic high manganese (Mn) steels are often used in harsh environments due to their high toughness and wear resistance.

November 06, 2023

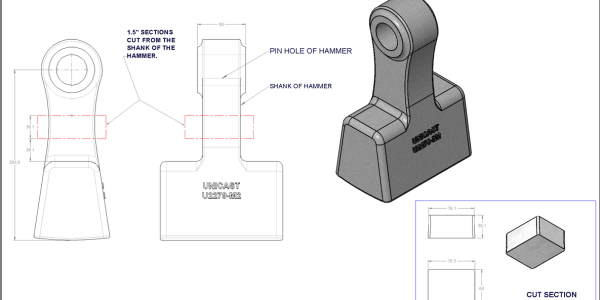

In-service Performance of High-Manganese Steel Clinker Crusher Hammer

This paper discusses the effects of elevated temperature exposure on the performance of austenitic high manganese steels at elevated temperatures.

June 06, 2023

Unicast wins industrial manufacturing award

Unicast is honoured to have received the Thompson-Okanagan Business Excellence Award in the Industrial Manufacturing category.