PRECISION ENGINEERED

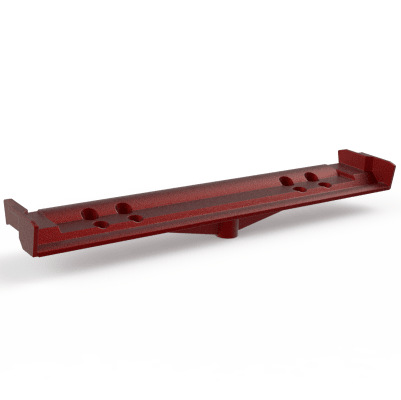

VALVES & PIPES

Built for performance. Delivered on time.

Tough, reliable, and built to last – our industrial valves offer unmatched quality and durability.

Unicast offers an industry best 25-year warranty on our advanced ceramic lined diverter valves. Unicast also carries stock of common sized valves and spare parts ensuring delivery times of 2-4 weeks depending on configuration.

Our diverter valves can be used in a variety of bulk material handling applications offering un-matched abrasion resistance. Our family of slurry valves can be ordered with abrasion and corrosion resistant linings for any mining applications. Our ceramic lined shut-off, and butterfly valves round out our valve offering.

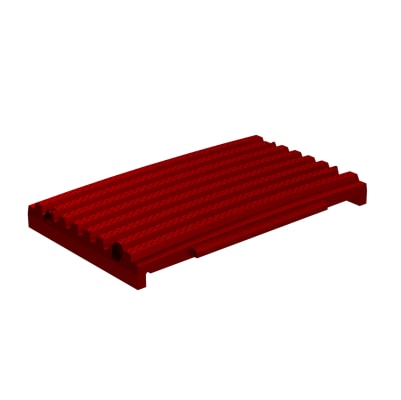

Unicast’s elbows and pipes use the same silicon carbide ceramic technology for unmatched wear resistance.

The gold standard for inline maintenance and durability.