- Home /

- Capabilities /

- Foundries

Foundries

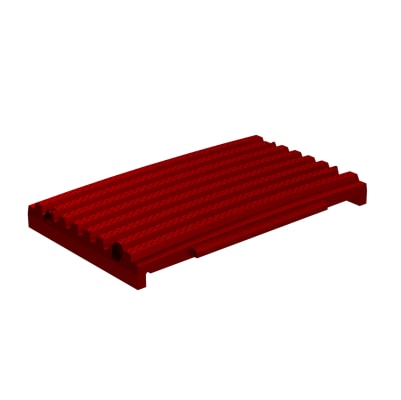

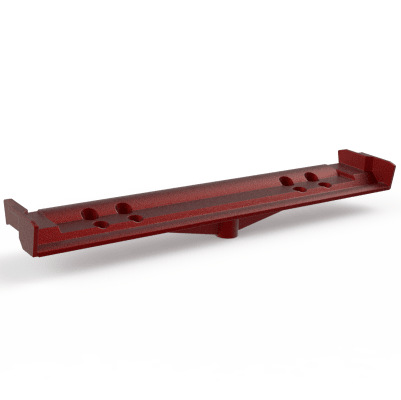

Unicast products are engineered by our dedicated team of in-house engineers in British Columbia and manufactured by our partner network of global foundries.

All of our foundries are world-class and are experts in producing specific wear part components. Their casting pouring capability ranges from 100 grams to 10 tons.

We visit partner foundries on a regular basis to review production scheduling, quality control and discuss technology advancements to fill clients’ needs.

Partner foundries are all certified ISO 9001 and equipped with Procast solidification and simulation software.

Partner foundries use the following equipment in their quality control process:

- Spectrometers

- UTM

- Brinell hardness tester

- Charpy impact tester

- Dye penetrant testing

- Ultrasonic testing