- Home /

- Industries /

- Cement

Cement Industry Solutions

Unicast wear parts and valves have improved productivity and minimized maintenance and downtime on global cement plants since 1994.

We sell cement industry wear parts and valves across Asia, South America and North America and our clients include the largest multi-national cement companies operating in the United States.

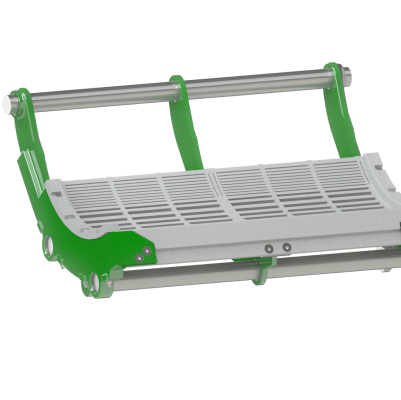

With a holistic approach to wear part design that improves the original part’s weight, weight distribution and alloy selection, our cement industry products include wear parts for gyratory crushers, cone crushers, jaw crushers, horizontal shaft impactors, hammermills, ball mills, feeders, valves, roller mills, kilns and coolers.

We have a rotating supply of in-stock wear parts ready for quick delivery, and we also specialize in customized and cost-cutting solutions designed for particular wear challenges.

Popular products include:

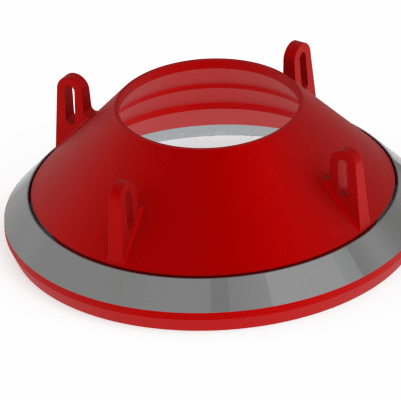

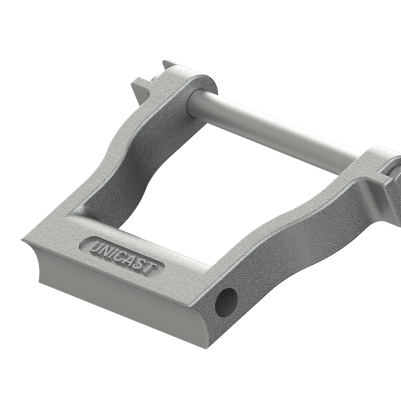

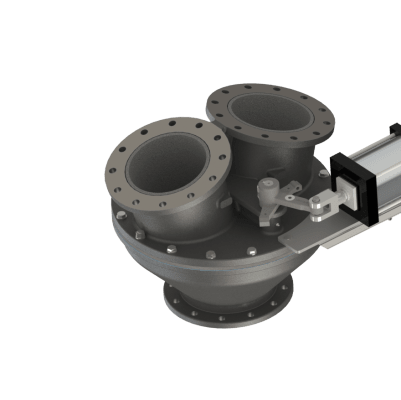

- Unicast’s flagship diverter valves set the industry standard for inline maintenance and durability. Valve maintenance can be completed in four hours without a crane or hoist, instead of freezing operations all day.

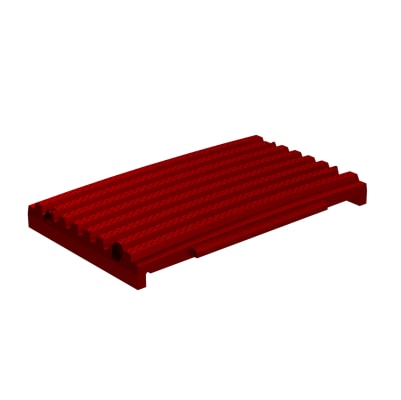

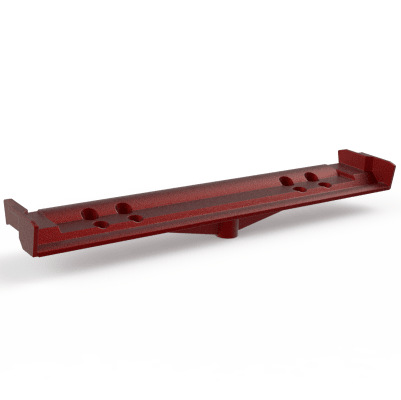

- Our one-piece hammers can improve hammer wear life by up to 350%. Base metal alloys for our hammers include austenitic manganese steel with or without tungsten carbide insert and wear alloy cast quench and tempered steel. Titanium carbide and ceramic inserts are also available.

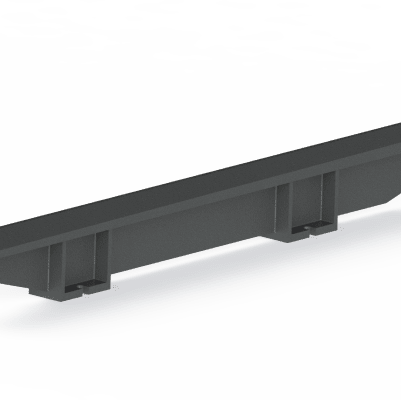

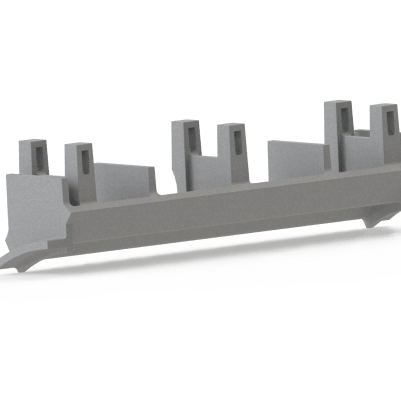

- Our blow bars are cast in high-strength quench and tempered steel and are three times the strength of carbon steel alone. Manganese and high chromium white iron steel alloys are also available, as are titanium carbide and ceramic inserts.