![]()

Titanium Carbide

Wear Parts

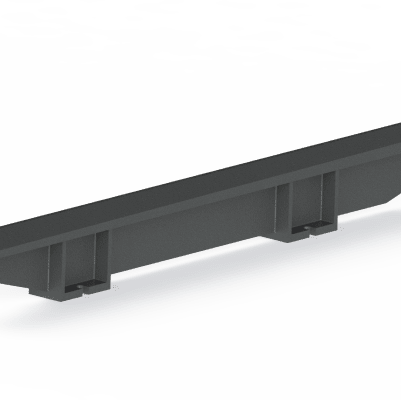

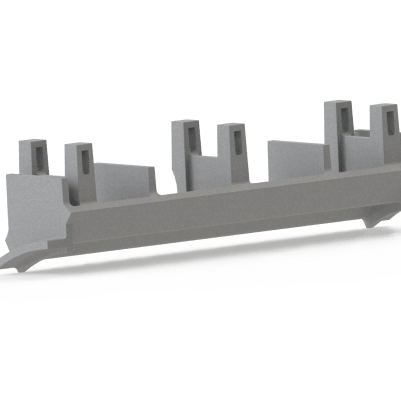

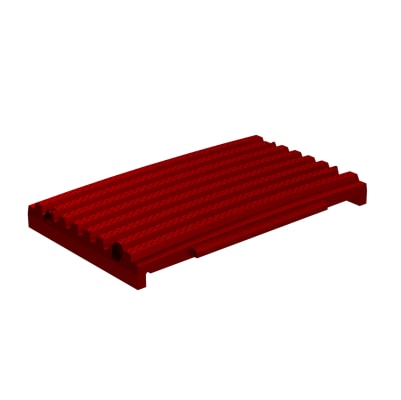

Unicast wear parts with Titanium Carbide (TiC) inserts deliver outstanding durability. Impactors/Blow Bars, Jaw Crusher Plates, Hammers, and Breaker Blocks are offered in TiC versions. We chose the rhino to symbolize the toughness of the titanium carbide rods that give our wear parts such power.

Advantages of Titanium Carbide

- Increased Wear Life - Unicast’s unique TiC hammer and blow bar design features a strengthened high-wear zone for maximum usable wear life and reduced breakage.

- Strengthens as It Works - Hammer body is cast in durable manganese steel (M19) that gets harder the longer you work it.

- Consistent Wear - More consistent wear profile for uniform product output and increased efficiency.

- Titanium Carbides - TiC inserts currently available are 20mm, 40mm, 60mm, and 80mm depths.

- Fewer Change-Outs - Greater durability and longer wear life means fewer change outs, more up-time, and lower maintenance costs.

Unicast Titanium Carbide Wear Parts in the Field

Case Study 1: Recycling Plant, 1213 Impactor Crusher (85% concrete, 15% asphalt)

Before: Competitor’s ceramic-embedded blow bars shattered after crushing 11000 Tons.

After Switching to Unicast TiC: Unicast M19 TiC Blow Bars crushed 38000 Tons: 3.45 X wear life!

Case Study 2: Cement Plant, 341lb Universal/ Pettibone Hammers (limestone)

Before: Competitor’s M8 hammers delivered a wear life of 450-600 hours before replacement.

After Switching to Unicast TiC: Unicast TiC hammers with 40mm pins averaging 1000-1300 hours: up to 2.22 X wear life! TiC hammers with 60mm pins projected wear life 1500 hours: up to 2.5 X wear life!

Case Study 3: Cement Plant, 1550 Pennsylvania Hammer Mill (limestone)

Before: Competitor’s high chrome hammer lasted for 2 weeks before breaking.

After Switching to Unicast TiC: Unicast TiC M2 Hammers and suspension pins lasted 8 weeks: up to 4 X wear life!